Add to Cart

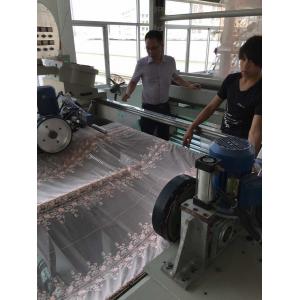

High quality Lace or Silk produced Textile finishing machinery , Efficient pin on

2. Technical data:

| Roller width: | 1400-3600mm | Working width: |

1200-3400mm

|

| Heating source: |

nature gas/ oil/ electricity/steam/any two combined

|

Width adjustment range: |

700-3400mm

|

|

Chambers No.

|

2-15 pcs | Temperature of chamber: |

100-230℃

|

| Fabric held by: |

clip/pin/combined

|

Air pressure: | above 0.5mpa |

| Padder type |

Finishing/Dyeing |

Installed power: |

Approx 140Kw

|

3. Different specifications for optional:

At the entry unit, the stenter can be equipped with Non-stop Accumulator/J-scray/Coating head/Pre-dryer etc.